Feeding Unit

● Servo motor independent drive, with Japan's Shimpo feeding speed reducer, high precision, no wear.

● The servo motor drives the roller type front feed.

● Can be a continuous or interval feeding.

● The installation of antistatic device.

● Eliminate dust because of electrostatic effects on the dust particles and not easy to brush.

Printing Unit

● The independent unit are dual servo motor drive, gearless cumulative error, printing, embossing, to achieve complete synchronization,

high clear image.

● The vacuum wheel transfer printing, can guarantee the warp sheet, cardboard printing.

● The roll correction device can quickly and easily produce tilt printed version of the correct hang.

● The precision control system can accurately adjust the ink imprinting gas, ink gap.

● The printing precision is ±0.15mm.

● Closed type double balde system, with ceramic anilox roll imported ink to ink device, can significantly improve the monochrome and multicolor printing dot and trapping effect.

Dryer Unit

● one unit drying unit

● Vacuum adsorption ceramic wheels transfer,more rows ceramic wheels dislocation array to strengthen cardboard transmission stability

● using infrared irradiating combined drying system for fast color fixing,guarantee the drying of ink between colors,avoiding

smudging.can directly follow the light oil,slotting,die cutting process.

● vacuum suctioned drying unit;independent servo drive(optional)

● entire process roller-type vacuum suction transport system.

● heating range can be chosen according to the cardboard size,the

● bellows damper can adjust by automatic according to the cardboard

● size:small,medium,large

● lift controlled transport table

● customers can choose three drying system according to their configuration:hot air or infrared or ultraviolet light.

● the drying system by the import PLC program automatic controlling,Man-machine dialog control and display

● Automatic temperature control, fault alarm protection, automatic detection alarm, fault status display

● Drying system with the host control starting and closing double protection, completely solve the cardboard directly irradiation time heat and burning this question when the machine stop.

Die Cutter Unit

● Independent servo motor drive

● All clearance adjustment are electric adjustable, touch screen display adjustment. The man-machine interface set automatic positioning.

● The selection of high quality steel precision manufacturing, surface grinding, hard chromium plating, durable.

● The electric adjustment and the knife mold roll gap.

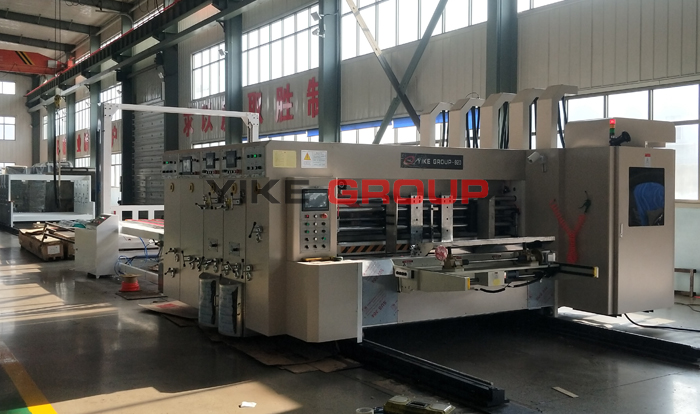

HS-1224 Automatic 4 color Printing slotting die cutter | ||

Max Machine Speed (pcs/min) | 250 | |

Economic Working Speed (pcs/min) | 200-220 | |

Max Feeding Size (mm) | 1200×2600 | |

Max Printing Size (mm) | 1200×2400 | |

Skip-feeding Size (mm) | 1450×2600 | |

Min Feeding Height (mm) | 250 | |

Plate Thickness (mm) | 7.2 | |

Suitable Cardboard Thickness (mm) | 2 - 11 | |

Min Slotting Distance (mm) | Negative Knife | 350×100×350×100 |